Capacity & Equipment

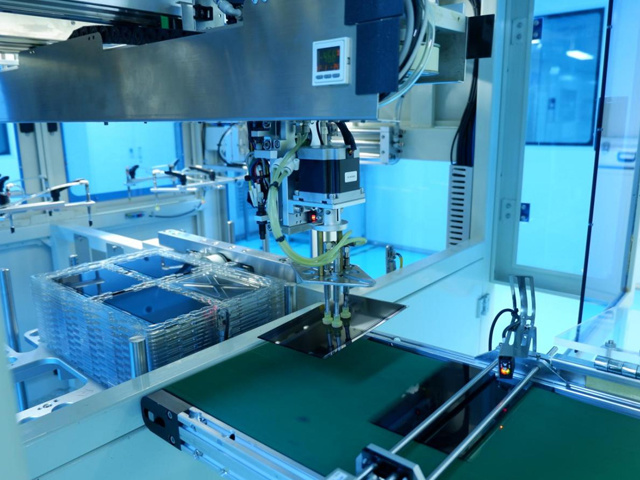

Automation Equipment Cluster for TFT Division

LCD Mall's production process is almost entirely completed by equipment, representing the advanced level in TFT LCD module manufacturing industry today.

POG Process

LCD substrate glass cutting

Small pieces glass put in baskets

Small piece glass 8 tanks washing + drying

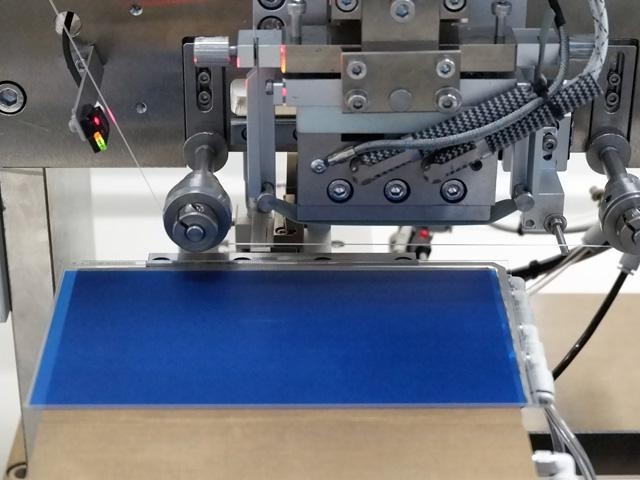

LCD electrical test

LCD washing

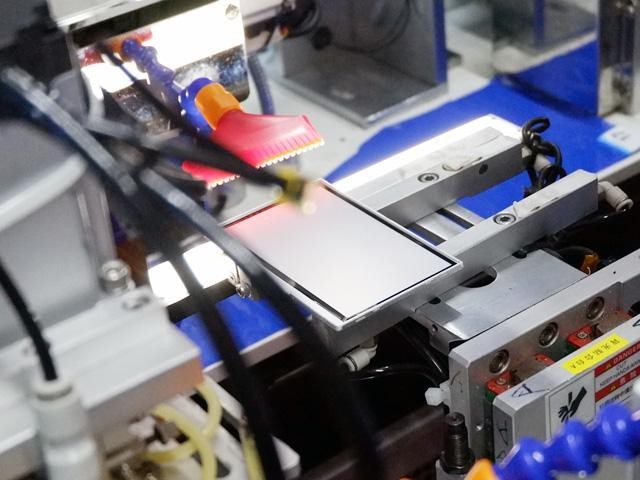

Equipment Attached Polarizers

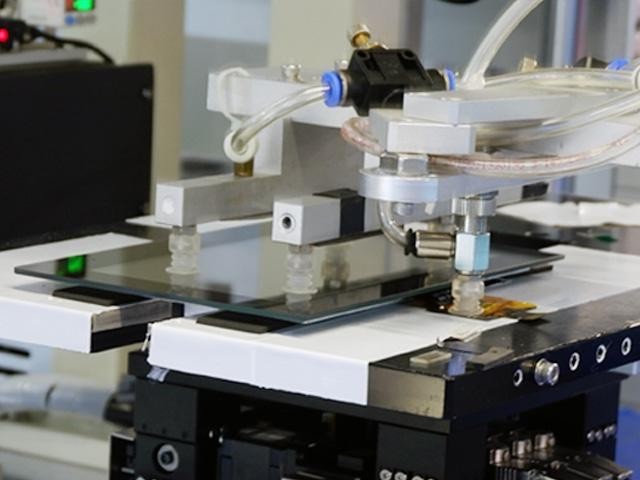

POG defoaming

POG electrical test

FOG Process

POG Loading equipment

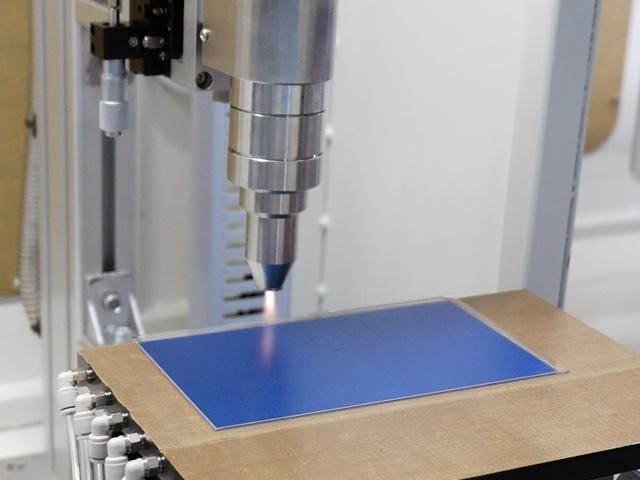

LCD step plasma washing

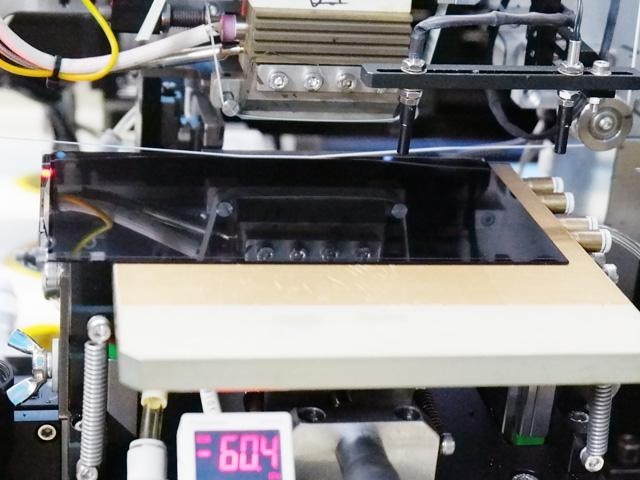

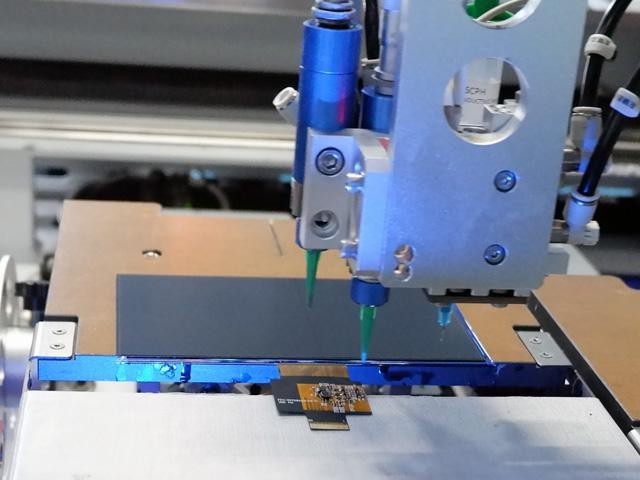

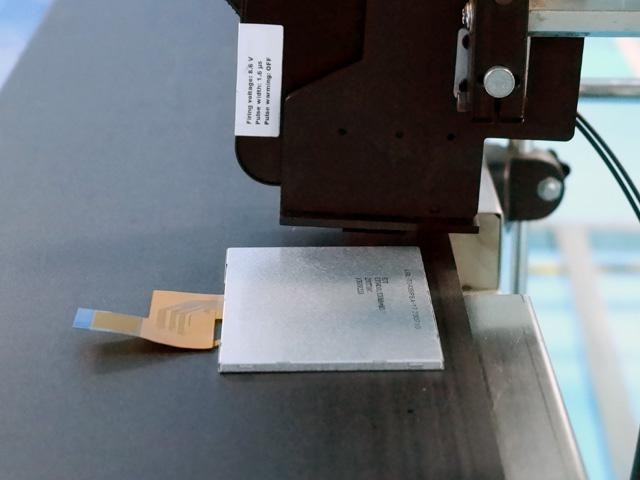

ACF attachment

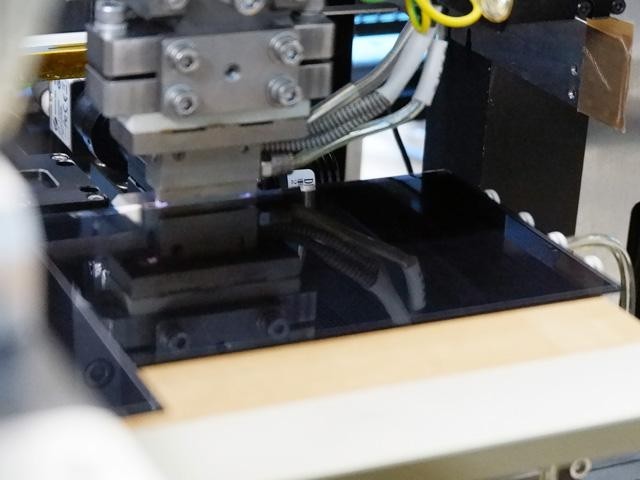

IC bonding

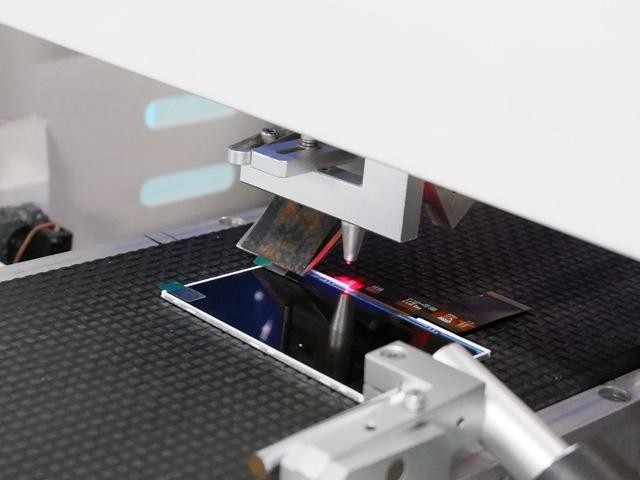

FPC bonding

AOI particle inspection

AOI particle inspectio

FOG electrical test

LCM Process

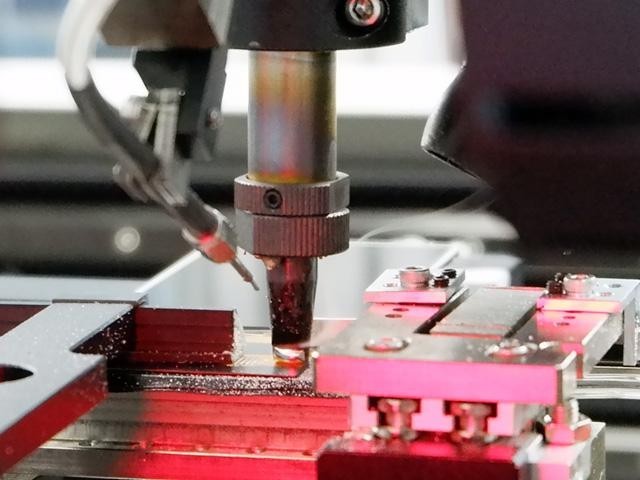

Equipment dispense glue

Automatic drying

Equipment assembly backlighting

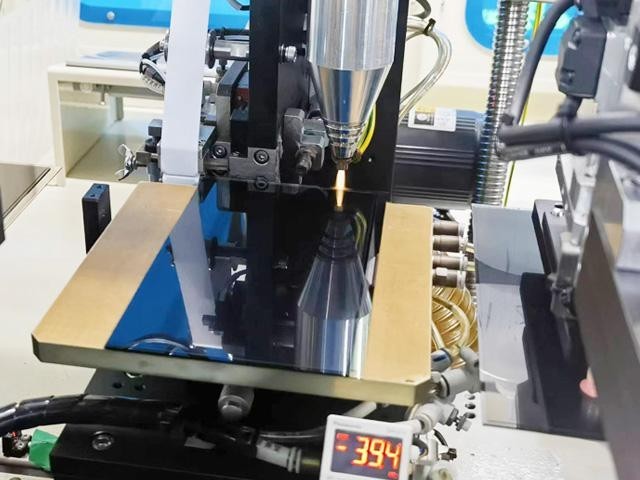

Automatic soldering

Equipment pull handle

LCM finished electrical measurements

Testing in the darkroom

Product Coding

CTP Process

Sensor plasma washing

Sensor ACF attachment

Sensor FPA bonding

Capacitive screen FOG electrical test and program burning

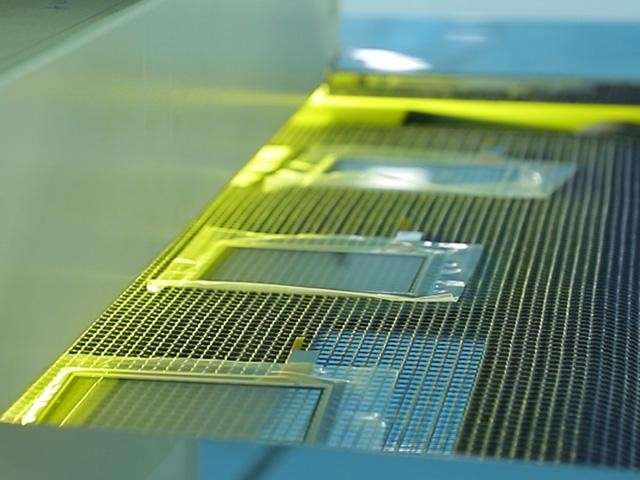

Cover lens OCA bonding

CTP defoaming

CTP scribing test

CTP UV solidify

Packing Process

Cover inspection and cleaning

LCM optical bonding

Accessories assembly

OQC final quality control

Exterior cleaning and applying protective film

Wrapping the LCM

Packing

Warehouse